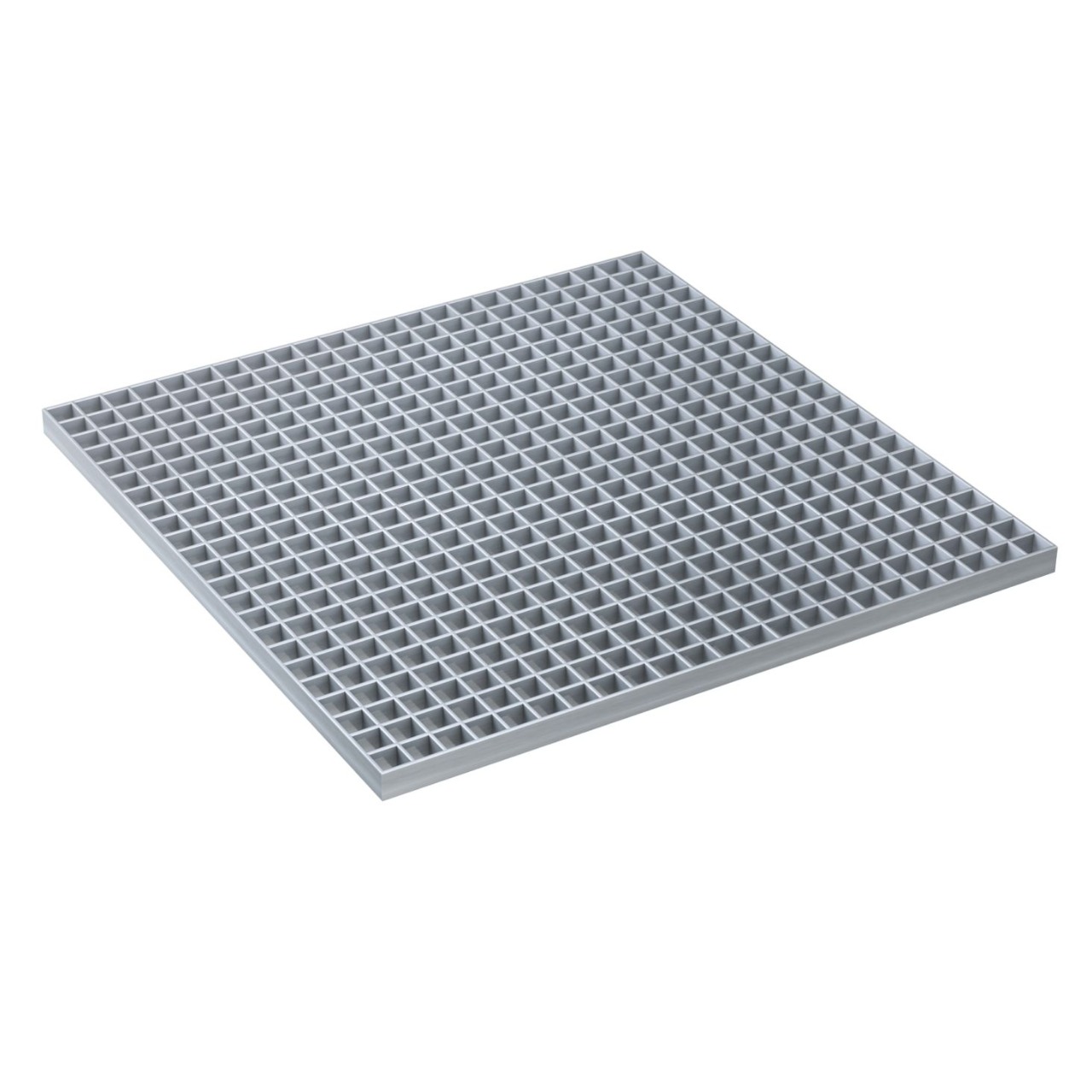

Moulded FRP/GRP Grating

Moulded GRP-gratings are produced in a negartive mould. The the

glass fibers are woven in a bond into the form. The resin mix is

produced in a mixing tool. The mix consist of the following resins:

Isophthalic resin, color pigments additives for fire behavior and UVinhibitors.

The mix is then also poured into the mould, the glass

fibers are pressed once more with a comb and the mould gets

heated. Heating hardens the material. When the grating has cooled

down, it is pressed out of the mould.

* All measurements are in milimeter

Material

Isopthalic Polyester Resin

Vinyl Ester Resin

Phenolic Resin

Top Surface Treatment

FRP grating is provided with an anti-skid Grit or Sanded (S) surface as standard. This is a coarse grit that is embedded into the top surface of the grating. A plain (P) top surface is available on request.

FRP Grating features

• high corrosion and weather resistance

• high chemical resistance

• hygienic and resistant to bacteria

• the gratings are load bearing in the direction of the supporting rods and the crossbars

• does not conduct electricity

• low thermal diffusivity

• Anti-slip up to R13

• relatively low unladen weight

• simple and quick on-site assembly

• high levels of comfort for walking and standing

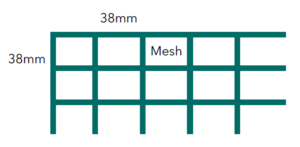

Standard FRP Grating Pattern

• Bearing bar pitch 38mm (center to center)

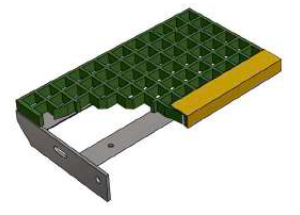

FRP Stair Tread

Welden Fixing

No Nosing

Available In